Offshore Intervention Service

Installation, Hook-up and Commissioning

Topside Fabrication and Fixed Sub-Structures

PIECURVE has its offshore work team from senior, experienced marine construction personnel up to supervisory level on a permanent basis. The construction team is supported on the platform by project personnel whose responsibilities are keyed to specific areas, systems and disciplines. These personnel are linked to the craft supervisors and establish priorities, interpret drawings, identify & rectify shortages, etc. Within an area, various disciplines work simultaneously, however, limited by safety considerations and reasonable access to the work. PIECURVE supervisory personnel and high level workers execute offshore activities for platform topside works as per the planned schedules.

PIECURVE offers complete spectrum of activities involving Pre-commissioning related works. Our engineers carry out quality checks and design validation in accordance with the P&IDs, assist in dewatering, inert gas purging and drying prior to flow of hydrocarbons.

Commissioning

Commissioning of facilities is generally carried out by owners or in conjunction with contractors. Nevertheless, PIECURVE’s expert commissioning engineers can be contracted to participate as third party reviewers. We will perform an independent review of the entire design and as-built drawings and facilities schedule and manual and provide an eagle eye review of the entire commissioning procedure before, during and after the commissioning.

Our scope of services includes:

- Co-ordination / Logistics with various Vendors and Contractors

- Keeping a check on all parameters during commissioning in accordance with the recommended practice.

- Assist in preparation of As-built documents

- Preparation of list / replacement list for Spare parts

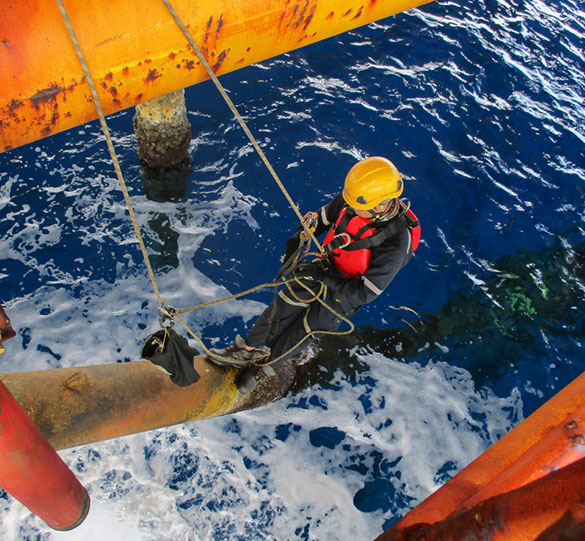

Rope Access

Following and strictly adhering to the most stringent regulations, codes and standard e.g. ASTM E2505-07, ANSI Z359 our expert team of technician can navigate and reach the remotest and most challenging offshore structures to carry out a comprehensive rope access inspection services or perform all work at height activities as required by our Clients. We achieve this while maintaining our safety records in delivering services that meets our Clients expectations. All our rope access technicians are IRATA and LEEA qualified. We can provide the following services:

- Inspection & Non-Destructive Testing

- Ultra High Pressure Water Blasting

- Painting (airless spray & brush application)

- Maintenance & Installation Projects

- Load Testing Services

- Electrical Maintenance

- Derrick Assembly

- Rigging & Lifting

- Grit Blasting

- Visual Inspection

- Welding Inspection

- Structural Survey

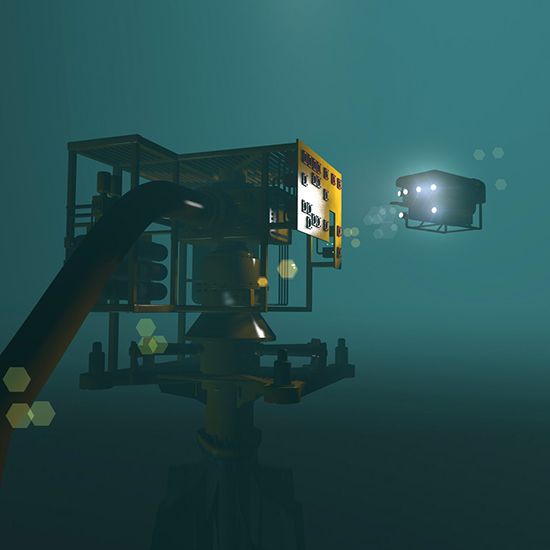

Underwater Inspection & Engineering Activities

- Offshore Right-of-Way Topographic Survey and Pre-installation surveys.

- Inspection of subsea structures e.g. PLETs, PLEMs, Trawl, Suction Piles, Subsea Pipelines, Subsea Bags and Mattreses.

- Non-destructive Testing / NDT / Spudcan & Mudmat Repairs & Inspection

- Underwater Photography, Video, CCTV, Core Sampling, Hydrographic, Eddy Current, Ultra Sonic, Sonal, Magnetic Particle Inspection.

- Diving Inspection

- Underwater Oxy Arc Cutting & Welding Services

- Cleaning of Underwater Marine Growth

- Repairs to Any Underwater Structural Damage

- Sealing of Stern Glands.

- Underwater Cleaning Of Ships Hull & Propeller Cleaning / SBM Maintenance & Surveys

- Inspection of Self Surfacing Anodes and Installing Cathodic Protection System.

- Diving Services for Drill Rig & Block Placing.